Introduction

Tech companies face the challenge of high costs and long development times for their prototypes. This has been a challenge for many companies. Conventional manufacturing practices have also been found to be inefficient. They have been unable to keep up with the need for speed. The main problem has been the choice of wrong suppliers and regional strategies. This has been due to the failure to have a global and optimized supply chain approach. This article presents a solution to the problem. This is through the comparison of the cost, technical reliability, and ecosystem benefits of the rapid prototyping services in the U.S. and China. The following sections will explore the critical aspects of the problem to create a substantive base for the decision-makers.

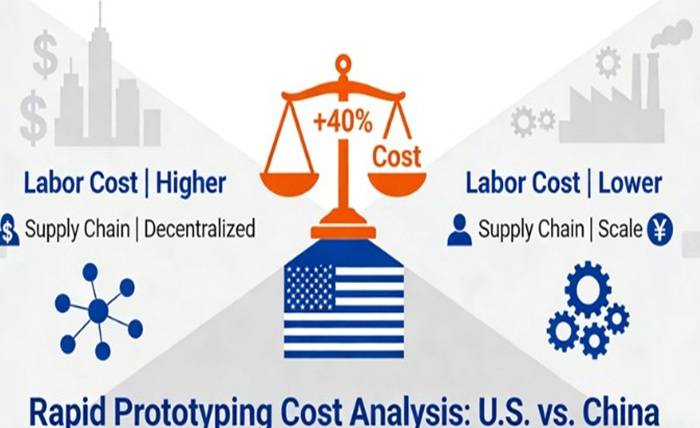

Why Can Cost Differences for Rapid Prototyping Services Reach 40% Between the U.S. and China?

The large cost difference, which is typically around a 40% variation, is not arbitrary but is instead based on a number of underlying economic and operational factors. Knowledge of these factors is essential to a strategic sourcing decision.

The Structural Foundations of Cost Advantage

The underlying factors in the cost difference between the U.S. and China are largely structural. For the Chinese, there is a massive economy of scale in the supply chain, which results in a lower cost of raw materials. In addition, data provided by the U.S. Bureau of Labor Statistics has shown that the manufacturing labor cost index in the U.S. is higher compared to the Chinese. The Chinese also enjoy a higher rate of equipment utilization, thereby allowing the fixed cost of the equipment to be distributed across more projects, thus lowering the cost per unit. In compare the prices of rapid prototyping service providers, the underlying factors in the cost difference explain a large part of the variation.

A Closer Look at Project Cost Structures

A good example of this is a metal part machining project. It is likely that the supplier, who is based in the U.S., will have higher individual line item costs for machine time and material. The service provider, however, in the rapid prototyping china ecosystem, will likely be using vertical integration, whereby more steps in the production process are conducted internally. This reduces the markups and transaction costs, enabling the service provider to be more aggressive in pricing without necessarily compromising the quality. The savings are most apparent in the direct manufacturing costs.

The Critical Role of Total Cost Assessment

However, a savvy decision-maker must look beyond the unit price.

l Logistics and Lead Time

Shipping the prototypes from China will cost money and create time-related issues. For extremely urgent versions of the product, a local supplier within the U.S. may be more cost-effective when the time to market is factored in as a cost.

l Communication and Revisions

Time zone differences and the possibility of language barriers may create some issues that require revising the work. The cost of the project management time should be factored into the overall cost assessment.A holistic approach is required. As analyzed in the resource US vs China Rapid Prototyping, a comprehensive analysis that includes these hidden costs is the key to a cost-benefit analysis..

How to Assess the Technical Reliability of Rapid Prototyping Services?

It is impossible to discuss cost without the concept of quality. The technical reliability of a service is of the utmost importance. A technically failing prototype can result in a project being delayed by weeks. The assessment of reliability requires a detailed analysis of certain technical parameters and quality standards.

The key parameters that define a high-precision prototyping services in the realm of prototyping services include tolerance accuracy (+-0.005mm), the capability of the equipment (+-5 axis CNC), and inspection processes that involve Coordinate Measuring Machine validation. Adherence to international standards that define a quality management system, such as ISO 9001, is the benchmark for reliability. Adherence to such standards minimizes the chances of receiving non-conforming parts. Precision Engineering Services is a concept that is defined by the parameters of quality. A technically failing prototype that does not fit or function because of inaccuracies can cause delays and cost overruns. This highlights the importance of working with a technologically competent service that uses advanced manufacturing technology.

How Can Rapid Prototyping Services Accelerate Tech Product Time-to-Market?

The main advantages of prototyping are realized in terms of faster development cycles, which reduce the risk of production. Time taken in prototyping directly results in faster product-to-market times, thereby providing a significant competitive advantage.

Improving Iteration Efficiency

Rapid Prototyping Solutions enables rapid testing of digital designs by means of physical prototypes. This creates a rapid feedback loop, where the process of designing, testing, and iterating is reduced from weeks to mere days. This allows for faster iteration of different design options, which results in an optimal solution being achieved much faster.

The Power of Problem Detection

The consumer electronics space, for example, is an area where form and function are critical. What if a company developing a smartwatch housing prototype discovers a problem with component interference before mass production tooling contracts are placed? A problem of this nature, which might be discovered during the prototyping phase, might only cost a company a few thousand dollars. On the other hand, a problem of this nature, which might be discovered during the mass production phase, might cause a company losses running into the six figures. This is what gives rapid prototyping companies a big edge over others.

What Common Pitfalls Should Be Avoided When Selecting a Rapid Prototyping Service?

Thus, the process of strategic selection needs to be proactive in avoiding these mistakes, which may counteract the benefits of prototyping. Awareness of the mistakes is the first step towards avoiding the mistakes.

The first mistake to be avoided is an overemphasis on unit prices without consideration of total cost of ownership, which includes logistical, possible rework, and project management costs. The second mistake is the lack of Design for Manufacturability (DFM) collaboration. The rapid prototyping agency should be knowledgeable enough to provide DFM feedback to enable an optimum design that meets the requirements while considering the process selected, which may reduce costs and improve quality. In addition, there are IP considerations. For example, it is risky if a good Non-Disclosure Agreement (NDA) is not obtained or IP protection is not included within the supplier’s processes. According to the SBA publication, there is a need for business to be cautioned on the importance of vetting their associates to avoid costly mistakes. When considering working with a rapid prototype company, it is essential to ask for quotations and be aware of their certifications and IP ownership, especially when considering Custom Part Production, where IP is part of the process.

How Do High-Precision Prototyping Services Meet Stringent Industry Standards?

Industries such as the medical industry, aerospace industry, and automotive industry have very high standards that need to be met, not only with regards to capabilities but also with regards to compliance.

These industries require that the prototypes be compliant with certain standards; for example, the medical industry requires that the prototype be biocompatible, while the aerospace industry requires that the prototype be able to withstand extreme temperatures and pressures, and the automotive industry requires that the prototype comply with stringent safety standards. For example, the JS Precision company requires certifications such as the ISO 9001, IATF 16949, and AS9100D standards, which are all derived from the ISO 9001 standard and aim to ensure that the prototypes comply with the stringent standards set by the automotive and aerospace industries.

Conclusion

In summary, the rapid prototyping services provided by the US and China have their own advantages. The cost difference between the two countries may vary by up to 40%. This is due to the economic conditions of the countries. However, the reliability of the technology is not related to the location. Rather, it is related to the equipment and processes used. An overall analysis of the total cost, technical capability, and strategic fit of the business can be done by the tech companies. This will help the companies optimize their business development. The hybrid strategy is the best option in this case.

For a personalized evaluation of your project needs and a free DFM analysis to save costs and speed up your project timeline, contact our expert team today.

Author Biography

JS Precision is an expert in the precision manufacturing sector with over 20 years of experience, specializing in rapid prototyping and mass production services for global technology clients.

FAQs

Q1: What is the usual lead time for rapid prototyping services?

A: The complexity of the project affects the lead time. In general, simple projects can be completed within 3 to 5 days. However, for high-precision projects, it may take two weeks. Chinese vendors can deliver quickly because of economies of scale, but logistics should also be considered.

Q2: How is security for intellectual property for prototype design ensured?

A: Intellectual property security is ensured by working with ISO-certified vendors, drawing up strict NDA agreements, and ensuring data transmission via an encrypted channel. Periodic auditing also helps.

Q3: What is the minimum order quantity for low-volume prototype production?

A: There is no MOQ, but orders for 10 pieces or more may qualify for volume discounts. It is recommended that orders are consolidated to optimize the cost.

Q4: What materials are available for the rapid prototyping processes?

A: The processes available are metals such as aluminum and titanium, plastics such as ABS and Nylon, and composites. The materials are chosen depending on the need to test the function of the parts, and this information is available from the suppliers.

Q5: What are the differences between the technical support provided by the U.S. and Chinese vendors?

A: The technical support provided by the U.S. vendors is more convenient, while the Chinese vendors provide more comprehensive DFM analysis. They can serve as a link between the two.