Before UV DTF printers printed crystal labels, there were already many types of stickers on the market. Like stickers, lettering stickers. So what is the difference between UV DTF crystal labels and these labels? Next, the differences between the above three aspects will be explained in detail from the definition of the product, the characteristics of the product, the application of the product and other aspects.

Product Definition And Production Process

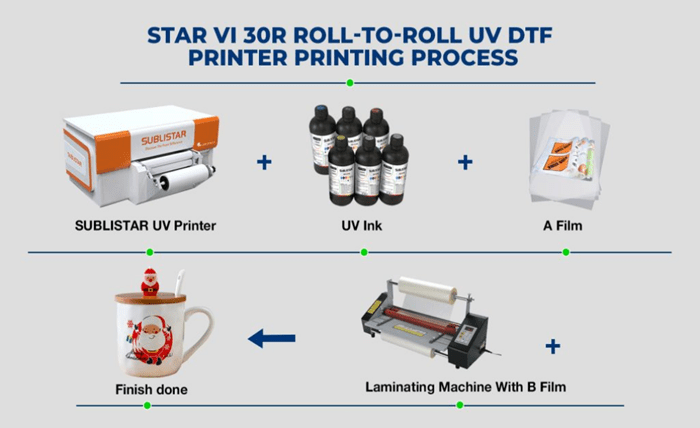

UV DTF printers use UV flatbed printers, UV roll-to-roll printers, or UV roll-to-plate all-in-one machines to print designs on A film and then cover B film. To transfer to the item, you need to tear off the A film first, and then print the pattern on the substrate, and press the pattern evenly back and forth by hand to make it completely transferred to the item. Finally, tear off the B film to complete the whole process.

Self-adhesive is a paper, film or special material for the fabric, the back is coated with adhesive, to silicon protective paper as the base paper of a composite material, the surface can be printed on a variety of patterns, and then after glazing, laminating, stamping die cutting and other processing to become the finished label. Use is very simple, directly tear off the bottom film, directly paste on the product can be.

Lettering paste, also known as instant paste, is a composite material made of paper, film or special materials, coated with adhesive on the back, and coated with silicon protective paper as the base paper. Lettering paste needs to be printed paste production, to be pasted on the screen above must be the inside of all the bubbles squeezed out, so that lettering paste flat attached to the gauze above, but be sure to pay attention to is affixed to the outside of the screen plate, can not be affixed to the inside, so that the screen plate is generally suitable for printing a small number of screens, can not be printed in large quantities, If the number of printing is too large for a long time, the lettering sticker may not stick firmly and fall down.

Different Product Characteristics

UV DTF crystal label film tear picture, film tear word, in addition to good pattern effect, there are good scratch resistance, waterproof, high temperature resistance and other characteristics, easy to paste, environmental protection, slightly convex texture, bright color, wide range of use, most of the hard smooth material surface can be very good paste.

Self-adhesive labels with traditional labels have the advantages of no brush glue, no paste, no dip in water, no pollution, saving labeling time, etc., a wide range of applications, convenient and fast.

The use of lettering paste should avoid the production of bubbles and needle eyes, the need to manually eliminate the excess part, so it is only suitable for some bold font design, too small place can not be done by hand and not good transfer.

Product Application Areas Are Different

UV DTF printing crystal labeling has a wide range of applications and is suitable for all hard material surfaces. Tea cans, water cups, paper cups, notebooks, tin cans, aluminum boxes, plastic, stainless steel, ceramic products, packaging boxes and other surfaces perform well. It is not recommended to stick on soft material items, such as cloth, leather, silicone, glazed ceramic or rough matte product surface, although it can be affixed, but the firmness and durability will be greatly reduced. UV printer currently has a new development, supporting the high luxury customization of hot gold or hot silver, which can be fully applied in the field of personalized, but also allow customers to DIY. The added value of the product is higher.

Self-adhesive labels are roughly divided into two types: first, paper self-adhesive labels, and second, film self-adhesive labels.

1, paper self-adhesive labels are mainly used in liquid washing products and popular personal care products; Thin film materials are mainly used in high-grade daily chemical products.

2, film self-adhesive labels commonly used PE, PP, PVC and some other synthetic materials, film materials are mainly white, matte, transparent three. Because the printability of the film material is not very good, it is generally treated with corona or by adding a coating to its surface to enhance its printability. It is mainly used for decorative decals on cars and motorcycles, logo words on trademark Windows, reflective film on highways, and marks on containers.

Engraved stickers are generally attached to the glass, or the surface is smooth and easy to paste, and have the role of warning or informing the purpose. Lettering paste in the use of the process need to pay attention to several points: choose the corresponding position to paste the sticker, the corresponding position of the dust or oil stains clean; Pay attention to the above and below and horizontal position of the sticker; It is recommended to spray some water on the glass and sticker before pasting, and finally adjust the position and scrape off the water with a scraper; Attach the transfer film to the lettering, attach the lettering together, and attach it to the glass. Don’t paste it all at once; If there are bubbles after the paste, prick it with a needle and then smooth it with a rag.

To sum up, each sticker has its corresponding application field, and it cannot be said that one is the best. It’s the fit that’s the best. All three are stickers, but their product characteristics determine that they are not the same way. All play their best role in their respective fields.